More Efficient Way To Defrost Cars Using Electricity To “Zap” Ice Without Heat

There are large swaths of America where in order to have a safe drive into work, one has to start their car even before their coffee machine.

Heating up a car and running the defrosters is a hugely energy intensive process, but researchers at Virginia Polytechnical Institute believe they’ve found a new and improved method for defrosting.

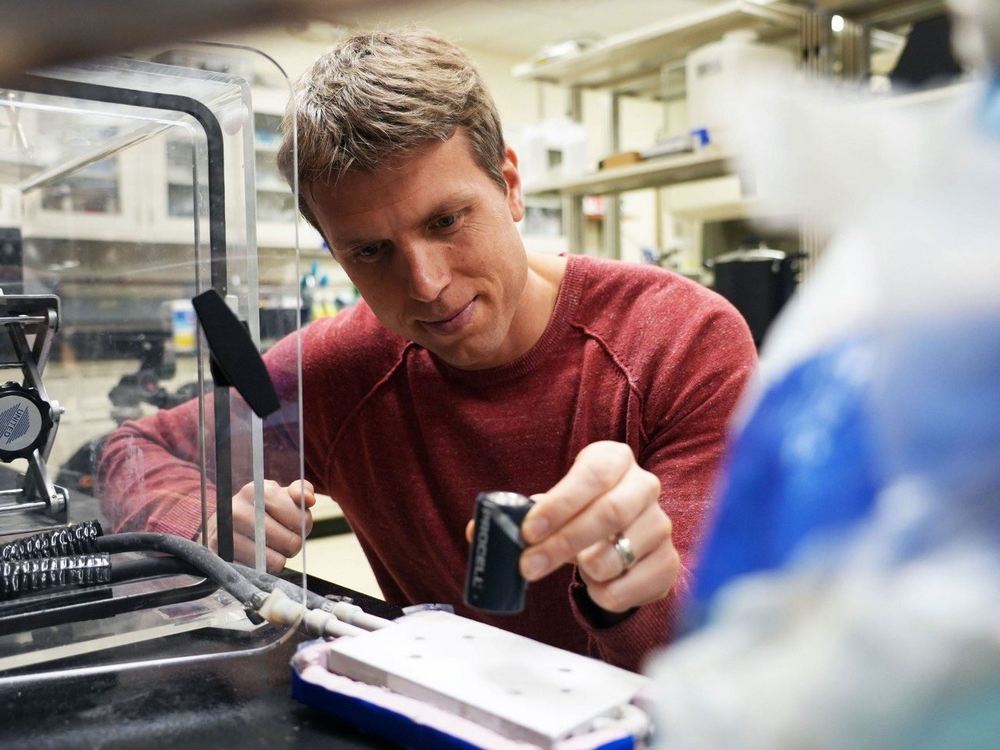

Mechanical engineering Professor Jonathan Boreyko’s philosophy is to combat ice by exploiting its own physics instead of using heat, which is energy-intensive, or chemicals, which pollute the environment.

The team’s previous work leveraged the small amount of voltage that naturally exists within frost to polarize a nearby water film, creating an electric field that could detach microscopic ice crystals.

By increasing the voltage the team developed a new method called “electrostatic defrosting” (EDF).

As ice crystals grow, the water molecules arrange into a tidy ice lattice. But Boreyko explained that sometimes a water molecule lands a little off-pattern—maybe it has an extra hydrogen, for example.

“Think of it as if you’re putting together a big jigsaw puzzle too quickly, so that a piece gets jammed in the wrong spot or is missing entirely,” said the professor in a press release from VA Tech. “These tiny errors create what scientists call ionic defects: places in the frost where there is a bit too much positive or negative charge.”

The team hypothesized that when applying a positive voltage to an electrode plate held above the frost, the negative ionic defects would become attracted and “migrate” to the top of the frost sheet, while the positive ionic defects would be repelled and migrate toward the base of the frost.

In other words, the frost would become highly polarized and exhibit a strong attractive force to the electrode. If that attractive force is strong enough, frost crystals could fracture off and jump into the electrode, but even without any applied voltage, the overhanging copper plate removed 15% of the frost.

IMPROVING EVERYDAY TOOLS: Innovative Tapeless Zipper Saves Tons of Fabric While Creating a Better Fit on Your Clothes

When the team turned on 120 volts of power, 40% of the frost was removed. At 550 volts, 50% was removed. At higher voltages, less ice was removed, until a strange contradiction in their theoretical model was corrected.

The research is continuing with the eventual goal of 100% ice removal.

Part of the research will include the removal of frost on multiple types of surfaces, expanding the potential applications across both industrial and consumer use.

MORE VA TECH RESEARCH: Plastic Waste Can Now be Turned into Soap Thanks to Eureka Moment from Virginia Tech

“This concept of electric de-icing is still in a very early stage,” said Boreyko. “Beyond this first paper, our goal is to improve EDF by reducing charge leakage and attempt higher voltages and electrode placements, among various other emerging strategies.”

“We hope that in the near future, EDF will prove to be a cost-effective, chemical-free, and low-energy approach to de-icing.”

Please be good and do not spam. Thank you.