New 3D-Printed Titanium Alloy is Stronger Than the Standard – Yet 30% Cheaper

Engineers from an Australian University have produced a new type of 3D-printed titanium that’s about a third cheaper than commonly used titanium alloys.

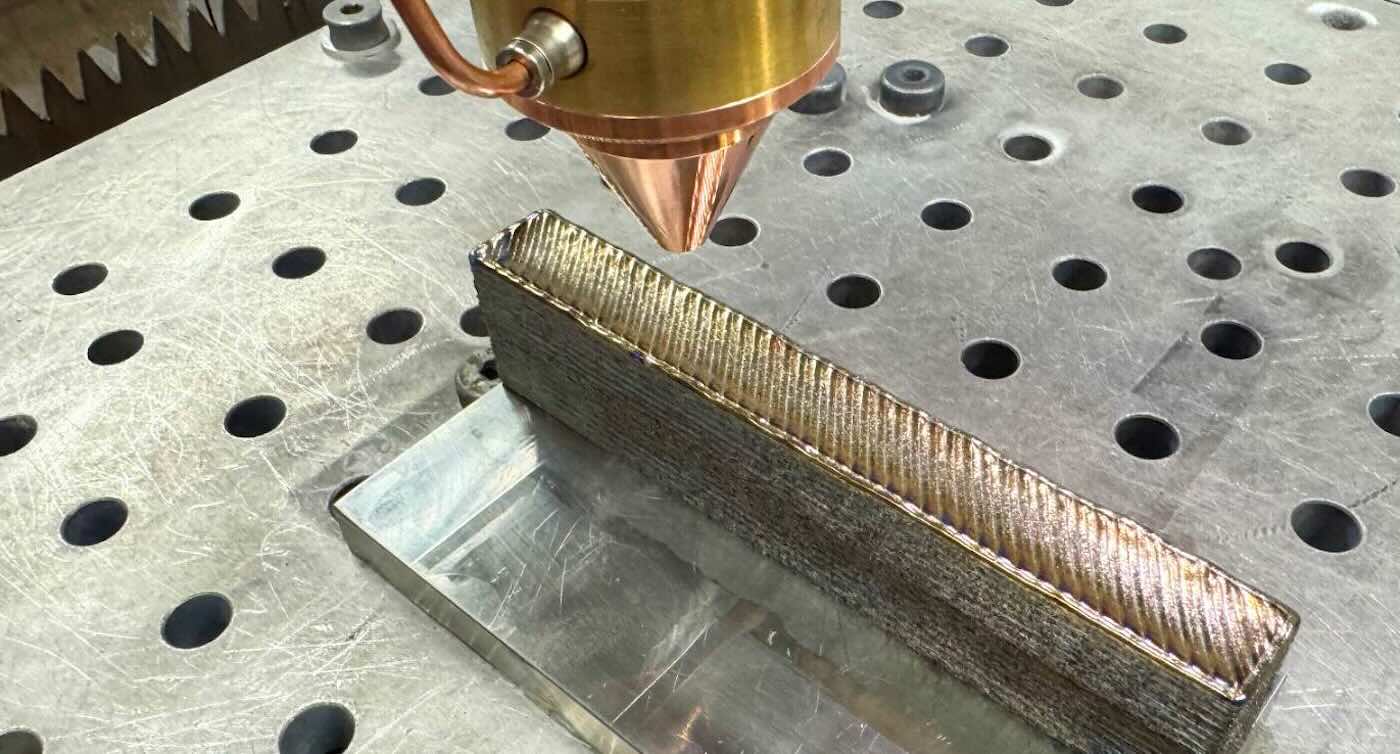

A team of engineers at the Royal Melbourne Institute of Technology (RMIT) developed the groundbreaking alloy by replacing expensive vanadium with more accessible elements. By rethinking how titanium alloys are designed, the team created a material with improved performance and more uniform microstructure—key factors for aerospace and medical applications.

The team has filed a provisional patent on their innovative approach, which has also been outlined in a paper published in Nature Communications.

The study’s lead author Ryan Brooke, working at the university’s Centre for Additive Manufacturing, will investigate the next steps of commercializing the technology, saying the field of 3D-printed titanium alloys was ripe for innovations.

“3D printing allows faster, less wasteful and more tailorable production yet we’re still relying on legacy alloys (like Ti-6Al-4V) that doesn’t allow full capitalization of this potential. It’s like we’ve created an airplane and are still just driving it around the streets,” he said in a university press release.

“New types of titanium and other alloys will allow us to really push the boundaries of what’s possible with 3D printing and the framework for designing new alloys outlined in our study is a significant step in that direction.”

Besides being nearly 30% cheaper to manufacture, the latest study outlines a time- and cost-saving method to select elements for alloying, providing a clearer path for predicting the grain structure so the metal can print more evenly, avoiding the column-shaped microstructures that lead to uneven mechanical properties in some 3D printed alloys.

“By developing a more cost-effective formula that avoids this columnar microstructure, we have solved two key challenges preventing widespread adoption of 3D printing,” said Brooke, a PhD candidate.

He recently talked to aerospace, automotive, and MedTech industry representatives about their needs.

“What I heard loud and clear from end users was that to bring new alloys to market, the benefits have to not just be minor incremental steps but a full leap forward.

“That’s what we have achieved here,” he said.

NEW MATERIALS BREAKTHROUGHS:

1) World’s First All-Timber Wind Turbine Blades are Cheaper, Recyclable, Fire-Resistant and Stronger than Carbon Fiber

2) Billions of People Could Benefit from This Breakthrough in Desalination That Ensures Freshwater for the World

3) This Innovation Could Extend Little-Used Zinc Battery Lifespan Hundreds of Times to Create Battery Revolution

“We have been able to not only produce titanium alloys with a uniform grain structure, but with reduced costs, while also making it stronger and more ductile.”

[Source: RMIT University]

Please be good and do not spam. Thank you.